By using our site, you acknowledge that you have read and understand our Privacy Policy.

SURFACE PIERCING PROPELLERS

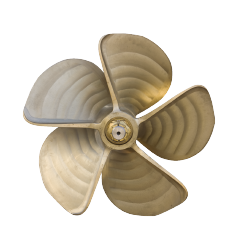

SUBMERGED PROPELLERS

UNRIVALED PERFORMANCE

SUBMERGED PROPELLERS

Operating below the waterline, fully submerged propellers are commonly used in vessels that require stability across different speeds as well as reliable, consistent thrust.

Back to results

Locate your local

Sales & Service Expert

Our extensive network of sales and service professionals is dedicated to providing comprehensive support for all your Twin Disc and Seakeeper needs. From product sales and installation to expert troubleshooting, maintenance, and genuine parts, we've got you covered. Find your local specialist today.

BACK TO FILTERS COLLAPSE RESULTS

Unfortunately, no sales, parts or service experts meet your current search requirements. To find more options, please modify your search criteria.

Consent for Google Maps has been denied. Use the LOCATE button to see distributors or allow Google Maps. Adjust Google Maps Consent

HAVE A NEED FOR OUR PRODUCTS AND SERVICES?

PUT THE POWER OF TWIN DISC TO WORK FOR YOU

Looking for a power transmission technology solution for your specific application? Twin Disc is more than ready to put horsepower to work for you.